| Payment Type: | T/T |

|---|---|

| Incoterm: | FOB,EXW |

| Min. Order: | 1 Bag/Bags |

Basic Info

Model No.: NM-AA00E,NM-AA00A

Additional Info

Packaging: Vacuum packing in wooden cases

Brand: Panasonic

Transportation: Ocean

Place of Origin: Japan

Port: Hong Kong

Product Description

Features

1.Longitudinal component feeders increase feeder carriage capacity for con-tinuous operation.

2.AVK2's Split feeder carriage system dramatically increases operation rate.

3.This is a variable pitch insertion machine, which still maintains the trade-mark random access system of the Panasert series.

So a sequence tapingmachine is unnecessary, and reinsertion can be performed immediatelywith a single switch when an

insertion error has occurred.

4.Self-correction function realizes high-quality insertion and high insertionrate.

5.The machine provides operation guidance on the color LCD screen, thusenabling interactive operation.

6.Information needed by the operator or for production management (errormessage, production management information, etc.)

can be displayed onthe monitor and can be printed out.

7.The AVK can be combined and finked with other Panasert machines.

Machine Specifications

| Applicable Electronic Parts |

Taped axial lead parts (carbon resistor, cylindrical ceramic capacitor, solid resistor, diode and taping jumper wire) Jumper wire (optional) Refer to 'Insertion Part Specifications' in this section for part dimensions. |

||

| No. of Part Inputs |

1. Taping width 26 mm •120 inputs (60 + 60) + Reel type jumper wire (optional) 2. Taping width 52 mm (Pack width: Max. 80) •120 inputs (60 + 60) + Reel type jumper wire (optional) 3. Taping width 26 mm and 52 mm can be used. |

||

| Part Packaging | Flat pack | ||

| Insertion Angle | 4 angles (X, Y, -X, -Y) | ||

| Insertion Tact Time |

Max. tact time: 0.15 s/point Max. tact time conditions according to part type and insertion angle

|

||

|

Applicable part Insertion angle |

Axial lead part | Jumper wire | |

| X direction (0°) | 0.18 sec/point | 0.15 sec/point | |

| Y direction (90°) | 0.15 sec/point | 0.22 sec/point | |

| -X direction (180°) | 0.30 sec/point | - | |

| -Y direction (270°) | 0.27 sec/point | - | |

|

Other conditions for max. tact time •Feeder carriage (both 26 and 52 mm component feeders) fixed •XY table movement: Max. 30mm for both X and Y (However,within 15mm for both X and Y when there are parts above 3mm high on the PC board. ) |

|||

|

Pitch Switchover within the Tact |

5 mm within the tact (0.15 sec/part) | ||

| Direction of PC Board Flow | Right to left | ||

| PC Board Replacement Time | Approx. 2 sec | ||

| Applicable PC Board Dimensions | Max. 508x381 mm Min. 50x50 mm | ||

| Insertion Area | Max. 508x371 mm Min. 50x40 mm | ||

| Insertion Pitch |

5 to 26 mm (Can be set freely by 0.01 mm increments.) 5 to 26 mm for jumper wire (optional) |

||

| Insertion Height |

Insertion height programmable according to the part diameter and lead diameter |

||

| Part Fixing System | Cut and Clinch system (piezoelectric detection system) | ||

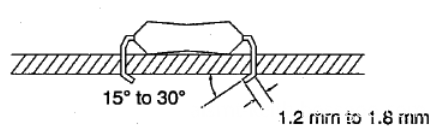

| Clinching Angle | 15° to 30° inner clinching | ||

| Clinching Length |

1.2 to 1.8 mm Note:The above numerical range indicates the variation which arise due to difference in the shape or material of insertion part leadsand the diameter of holes of PC Boards. |

||

CONTACT US

Shenzhen Keith Electronic Equipment Co., Ltd.

Address: Honghai Business Center 521, Songgang Street,Shenzhen,Guangdong

Contact Person: Nicolas

Phone:86-0755-23284593

Mobile:13828824221

Fax:

mail:nicolas@aismtks.com